When Is cross-docking Used in 3PL companies is used

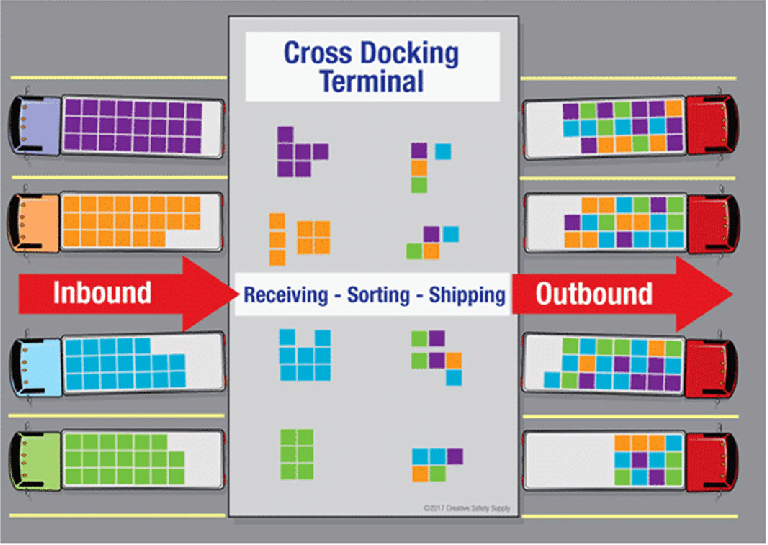

When is cross docking used in 3PL? This process is the process of loading and unloading a container from one truck into another waiting truck. The purpose of cross docking is to combine materials from different origins and sort them for different destinations. It can also be used to switch conveyance types. It is most effective when combining shipments from multiple vendors to one customer. But there are times when it is not possible to cross dock shipments.

A common use for cross docking is in the manufacturing process. Here, a 3PL receives products from one manufacturing plant and sends them to another. Distributor Cross Docking is used when a sales order consists of different vendors. In this case, a 3PL team depalletizes the products, collects all the components necessary to complete the order, and packs them on a pallet. Finally, the finished order is shipped out on an outbound vehicle.

Many businesses set up shipping arrangements with trucking and logistics companies to streamline the delivery process. This makes use of parcel delivery systems for their on-demand business. But a number of businesses still want to save space and eliminate costly middle operations. With cross-docking, these costs are reduced. Additionally, a more efficient cross-docking process improves profitability of facilities. So, if you’re in the retail business, it’s time to consider 3PL cross-docking.

Cross-docking allows you to avoid reloading the same product twice.

The process allows for product to be unloaded and reloaded at a 3PL facility near the destination. The third party then performs the final delivery to the retailer. This method is a cost-effective solution for retailers. If you have a truckload of products, cross-docking is the best option.

In cross-docking, one method of transportation is diverted to another. This process can save money and time in a number of ways. For example, in a 3PL warehouse, an order can be shipped from one warehouse to another without having to go through another warehouse. In addition, it can also reduce the cost of storage. And this can also lead to higher productivity. In short, it’s better to be efficient in supply chain logistics.

For some businesses, cross-docking is an efficient way to streamline inventory. The main benefit is that it allows you to streamline the process by making it more flexible. It also eliminates the need for warehousing. The only downside to this method is that it requires a third party’s warehouse. This makes it a very expensive way to fulfil large orders. On the other hand, the costs of storage are also reduced.

Cross-docking is useful in a variety of industries, especially eCommerce.

It helps companies streamline their logistics processes. For instance, it removes the storage link in the supply chain. For a 3PL, this method eliminates the need to store products in a warehouse. This way, the company can fulfil more orders faster and more efficiently. When used properly, cross-docking can save time and money.

While not all warehouses can benefit from cross-docking, there are some instances where it is an ideal solution. Using this process can streamline the supply chain of a certain product. The process can be used for products that need to be preserved or are otherwise temperature-controlled. In this way, the distribution of such products is streamlined. Further, it is a good way to consolidate smaller product loads.

In 3PL, cross-docking is a practice of loading a trailer from an incoming shipment. Usually, this process takes a relatively short time. In contrast, the logistics process is a complex one. In contrast, cross-docking allows multiple shipments from different vendors to be combined and unloaded in one location. The cross-docking process is a common way to streamline supply chains.

Cross-docking is a common way to improve efficiency.

It helps companies avoid unnecessary steps that would normally be involved in setting up a conventional warehouse. Similarly, it helps companies avoid the time and cost of deconsolidation. But it is not without problems. To understand its benefits, it is important to understand how it works. In a three-dimensional (3D) environment, a truck can be parked in one location while the other is unloading a pallet.

Recent Posts

Watch our Podcast

THE ULTIMATE GUIDE TO FREIGHT SHIPPING THROUGH FLORIDA PORTS

When it comes to ocean freight shipping in Florida, there is a lot to know to ensure you follow the appropriate steps when shipping into and out of Florida Ports.

Just enter in your email address and receive your FREE E-Book in minutes!