What Is Cross Docking? (Simple Explanation & Uses)

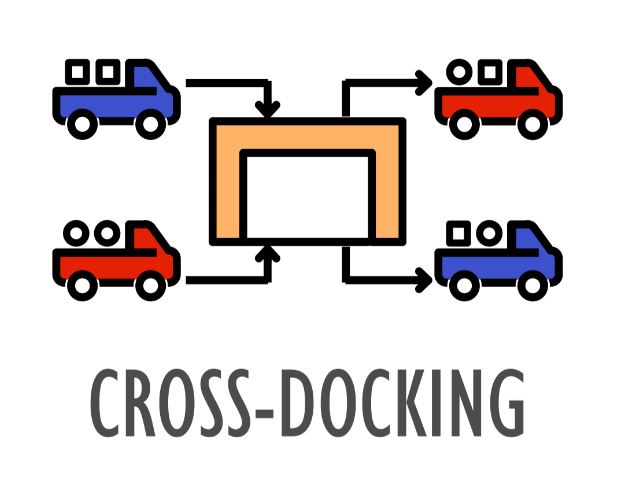

Cross-docking refers to the process of transferring goods from one carrier to another without unloading the shipment. It is mainly used in the transportation industry and its main purpose is to reduce the time that the product spends in transit by doing consolidation arrangements, But what is cross-docking and how does it work?

Let’s take a look at what exactly cross-docking is and what are the benefits of it.

What is cross docking?

The term crossdocking refers to the process of products move from one mode of transportation (i.e., truck) to another mode of transportation (i.e., rail). The end result is that the product will move directly from a supplier to a customer without being stored in a warehouse or distribution center. These results in inventory cost savings and improved efficiency within the supply chains.

Crossdocking can be used for all kinds of products, but it is especially useful for perishable goods that need to be processed quickly and efficiently.

Types of cross docking

Pre-Distribution and Post-Distribution are the two simplest types of cross-docking. Pre-Distribution involves unloading, sorting, and repacking goods based on predetermined distribution instructions. To put it another way, the customer is determined well before the goods depart the supplier’s warehouse.

The cross docking strategy and process involves:

- Unloading the shipment directly from the truck onto a conveyor belt, which takes the product to a storage area or directly to an outbound truck.

- Inspecting and cleaning any damaged products before they are placed on the conveyor belt.

- Loading the cleaned, undamaged products onto outbound trucks using automatic equipment such as lift gates and palletizers (which automatically place multiple boxes onto a pallet).

What does cross dock mean?

Cross Docking is a method of replenishment where products are received, inspected, repacked and shipped out without being stored in the warehouse.

Cross Docking involves receiving products from suppliers, removing them from their shipping containers and placing them on pallets or skids. The items are then sorted by SKU or other criteria and placed in storage bins or racks for further processing. This can include the transfer of goods between different transportation modes (e.g., railcar to truck) or between different carriers (e.g., airline to railroad).

How much does cross-docking cost?

Companies typically spend between $4-7 per square foot for warehouse space, which translates into a great deal of money. Using cross-docking allows you to reduce the amount of storage space that is required, thereby helping you to save on overall costs. Reducing carrying costs of inventory is one of the main benefits of cross-docking.

When it comes to small businesses that don’t have a lot of space or a large inventory, cross docking can be the perfect solution. As well as cutting shipping costs, it can eliminate the need for multiple shipments and returns.

It usually costs around 10% of your total sales volume per year for cross docking, depending on your industry and location. For example, if you operate a company making $100 million a year in sales, then your total annual costs will probably be in the range of $10 million.

How to implement cross docking?

Implementing cross docking involves four steps:

- Planning – You need to understand how your company will benefit from cross-dockingbefore implementing it.

- Identifying Opportunities – Once you’ve determined that cross-docking makes sense for your company, you can begin identifying opportunities to implement it.

- Performing a Cost/Benefit Analysis – A cost/benefit analysis will help you determine if the benefits outweigh the costs of implementing cross-docking.

- Implementing Cross-Docking – Once you’ve completed these first three steps, it’s time to begin implementing your plan.

What is cross docking warehouse?

Cross docking is a type of warehouse that is used by manufacturers and retailers to receive, store and ship out products. The term cross docking refers to the practice of moving goods directly from one transportation mode to another, without first unloading them into a warehouse space or other storage facility.

In a cross-dock operation, trucks arrive at the traditional warehousing, their cargo is unloaded onto a conveyor belt, then moved directly to another truck or rail car for shipping.

When is cross docking used?

Cross docking is often used for high-volume items such as electronics, apparel and other consumer goods that can be shipped directly from the distribution center to retailers or wholesalers without being placed on shelves.

Further, cross docking can be used for both import and export shipments, and it can be used for any type of cargo that needs to be transferred from inbound and outbound shipment. Some common examples include transferring containers from ocean vessels onto rail cars or truck trailers, distribution center or vice versa, or transferring pallets from a truck trailer onto a rail car or vice versa.

Recent Posts

Watch our Podcast

THE ULTIMATE GUIDE TO FREIGHT SHIPPING THROUGH FLORIDA PORTS

When it comes to ocean freight shipping in Florida, there is a lot to know to ensure you follow the appropriate steps when shipping into and out of Florida Ports.

Just enter in your email address and receive your FREE E-Book in minutes!